The Benefits of Using Cap Plugs for Sealing and Protecting Industrial Equipment

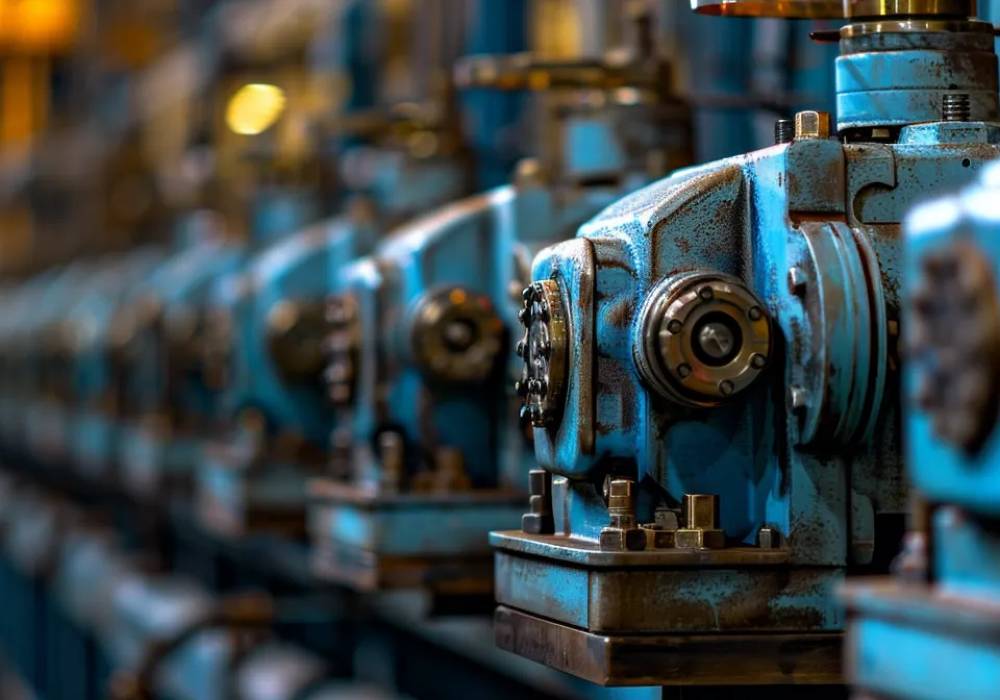

Industrial equipment requires meticulous care and maintenance to ensure optimal performance and longevity. Among the elements of proper equipment care, the use of cap plugs stands out as a pivotal component.

These small but mighty devices play a crucial role in protecting machinery from contaminants and damage during both storage and operation. Protecting your equipment can result in reduced downtime and lower repair costs, ultimately affecting your bottom line. Below, we delve into the world of cap plugs and how they benefit industrial equipment maintenance and protection.

Contents

- 1 Understanding Cap Plugs and Their Role in Industrial Equipment Maintenance

- 2 Enhancing Equipment Longevity with Proper Sealing Techniques

- 3 The Versatility of Cap Plugs in Various Industrial Applications

- 4 Cost-Effective Solutions for Equipment Protection with Cap Plugs

- 5 Streamlining Maintenance Processes through the Use of Cap Plugs

Understanding Cap Plugs and Their Role in Industrial Equipment Maintenance

Cap plugs, also known as end caps or protective caps, are essential for shielding pipes, rods, and tubes from dirt, dust, and other contaminants. They help maintain the integrity of critical components by preventing environmental damage and protecting delicate threads and edges during transport. Cap plugs serve various maintenance roles, such as masking areas during painting or coating processes.

Choosing the right cap plug is vital for effective maintenance, as they come in various materials like plastics and metals, designed for specific pressure levels and conditions. For reliable options tailored to diverse industrial needs, sourcing from a reputable supplier is key to ensuring the ongoing protection of valuable machinery.

Enhancing Equipment Longevity with Proper Sealing Techniques

Industrial equipment longevity is not just about the quality of machinery but also about proper maintenance. Proper sealing techniques, such as using cap plugs, prevent premature wear and tear, ensuring tight sealing when not in use. Cap plugs also absorb shocks and impacts, preventing dents or deformation.

Modern cap plug materials are durable and resilient, making them withstand rough handling. Regular sealing schedules can eliminate environmental exposure risks, especially for equipment in harsh conditions or outdoors. Choosing the right size, shape, and material is crucial for achieving protection. Maintaining a well-stocked inventory of cap plug dimensions helps maintenance teams respond effectively, fostering proactive equipment care.

The Versatility of Cap Plugs in Various Industrial Applications

Cap plugs are versatile industrial components that can be used in various sectors, including aerospace, automotive manufacturing, medical, oil rigs, petrochemical, electronics, and home appliances. They are essential for safeguarding essential equipment, ensuring sanitation and sterility, and preventing contamination and pipeline integrity. Their design allows them to fit unique and complex geometries, making them essential for maintaining safety standards in these fields.

Cap plugs can also withstand extreme temperatures and corrosive environments, making them suitable for various applications. Their adaptability and ability to meet specialized demands underscore their importance in maintaining and sustaining industrial infrastructures. The market for cap plugs is growing due to their adaptability and ability to withstand extreme temperatures and corrosive environments.

Cost-Effective Solutions for Equipment Protection with Cap Plugs

Cap plugs are a cost-effective solution for equipment maintenance, preventing significant financial losses due to equipment failure or unscheduled maintenance. They are easy to install and remove, reducing time spent on maintenance procedures and labor costs. Businesses can also purchase cap plugs in bulk from dedicated suppliers, ensuring a ready stock and volume discounts.

Incorporating cap plugs into preventive maintenance strategies can result in fewer emergency repairs and reduced equipment replacement rates. This avoids higher expenses associated with reactive equipment management.

The correct use of cap plugs ensures the safe and efficient operation of machines, leading to longer service intervals and reduced wear-and-tear. The modest investment in quality cap plugs leads to significant savings compared to the potential costs of extensive equipment repair or replacement.

Streamlining Maintenance Processes through the Use of Cap Plugs

Cap plugs are a crucial tool in industrial maintenance routines, allowing for faster and more efficient inspections and repairs. They are available in various colors, which can be used to indicate different maintenance categories or service intervals, speeding up the process. Cap plugs also simplify the identification of maintenance checkpoints, as they are easily visible and can be trained on.

This intuitive design reduces training times and ensures consistency in maintenance practices, ensuring all personnel are equipped with the necessary skills to maintain equipment reliability. Cap plugs also enhance safety procedures, as sealed ends can prevent accidents related to spillage, leaks, or exposure to hazardous materials. Thus, cap plugs play a vital role in maintaining operational safety in any industrial workspace.

Overall, the strategic use of cap plugs in industrial environments offers a multitude of benefits. These small components deliver significant impact in terms of prolonging equipment life, maintaining safety standards, and enabling cost-effective operations. As a result, cap plugs should be a staple in any maintenance and protection plan to ensure seamless, long-term performance of industrial machinery.