Advanced Technologies Transforming Industrial Pumping Solutions

Industrial pumping systems are the backbone of countless sectors, from mining and construction to oil, wastewater, and chemical processing. These systems manage the movement of abrasive slurries, high-viscosity fluids, and corrosive substances in environments where reliability, efficiency, and durability are non-negotiable.

Over the past two years, global energy and utility markets have witnessed significant volatility, resulting in price fluctuations, greater economic uncertainty and more regulation. In the wake of competitive pressures and tighter profit margins, pump and rotating equipment (PRE) manufacturers, who create things like a Float switch, are looking to smart operating models that focus on the customer by enhancing user-experiences (UX) and creating sustainable value.

As industries evolve and demand more from their equipment, technological innovations are rapidly reshaping the capabilities and expectations of pumping solutions.

Traditional pump systems, while effective in the past, often fall short in modern applications due to energy inefficiency, high maintenance needs, and limited adaptability to changing fluid compositions.

To address these challenges, the pumping industry is undergoing a significant transformation, one driven by smart technologies, improved materials, and system automation. Here’s a closer look at how cutting-edge advancements are redefining industrial pumping solutions and offering powerful advantages to today’s operations.

Contents

Innovation in Pump Design and Functionality

The first and perhaps most impactful change in the world of industrial pumps is the innovation in design. Traditional centrifugal pumps, though common, struggle when handling viscous or abrasive materials, often resulting in clogs, wear, and breakdowns. Modern pump designs are now addressing these issues by rethinking how fluids are moved.

For instance, vortex and peristaltic pumps offer non-contact and low-shear handling of solids and slurries, making them ideal for harsh industrial applications. But the real game-changer is the advent of eddy current-based systems. Unlike conventional impellers, these systems use a recessed rotor that creates a swirling action to transport materials with minimal contact and reduced wear.

It’s no surprise that the experts at EDDY Pump say that industrial operations using their patented technology report improved uptime, reduced maintenance, and greater adaptability across multiple sectors. This kind of innovative thinking marks a major departure from one-size-fits-all designs, allowing pumps to be tailored for specific tasks with remarkable precision.

Smart Monitoring and Predictive Maintenance

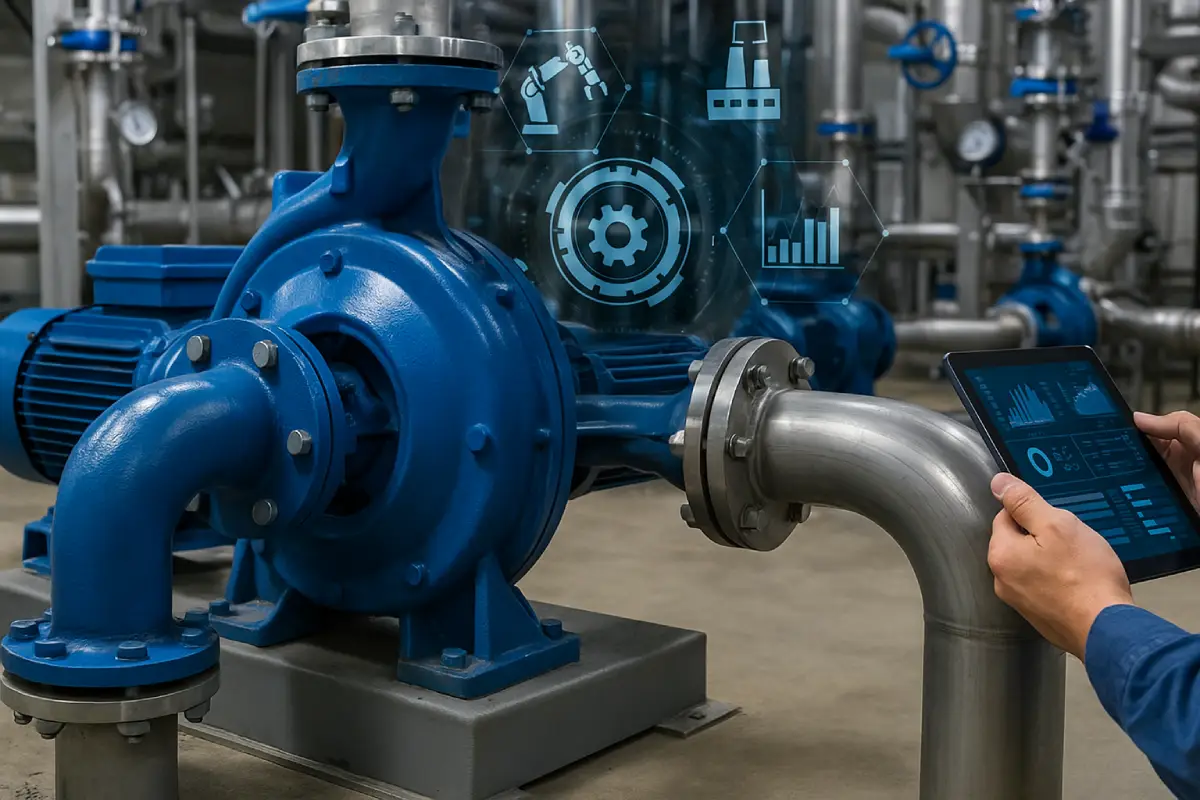

Industrial downtime is costly, and unplanned pump failures can disrupt operations for hours or even days. To combat this, intelligent pump systems now come equipped with embedded sensors and Internet of Things (IoT) capabilities that enable real-time monitoring of pressure, flow rate, temperature, vibration, and other critical parameters.

These smart pumps continuously collect performance data, which is then analyzed through cloud-based platforms or on-site interfaces. The result is predictive maintenance, identifying issues before they lead to failure. Alerts can be sent directly to operators or maintenance teams, who can then take proactive steps to resolve anomalies.

This predictive approach extends the life of the equipment and reduces the need for manual inspections, and minimizes unscheduled service interruptions. For high-volume or mission-critical industries, this translates into significant cost savings and operational stability.

Integration with Automation and Control Systems

Another major development in industrial pumping is seamless integration with automated control systems. Pumps are no longer standalone devices, they are now integral components of broader process control networks.

With the help of programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, operators can manage pump performance remotely, adjust operating parameters, and even automate response actions based on sensor feedback.

Automation enhances both efficiency and consistency. For example, variable frequency drives (VFDs) adjust motor speed in real-time to match demand, reducing energy consumption and extending component lifespan. Automated valve coordination, load balancing, and emergency shutdown protocols ensure that the pump system adapts to changing conditions without manual intervention.

This level of integration empowers plant managers to optimize system performance across multiple assets, enhancing productivity while maintaining strict compliance with safety and environmental regulations.

Use of Advanced Materials and Coatings

Material science plays a critical role in extending pump lifespan and performance, especially in environments that involve abrasive, corrosive, or high-temperature fluids. Modern industrial pumps now incorporate advanced alloys, ceramics, and polymer composites designed to resist wear and chemical degradation.

Innovative coatings, such as ceramic-reinforced epoxies or fluoropolymer linings, offer additional protection against pitting, scaling, and corrosion. These enhancements significantly reduce the rate of mechanical failure and lower the frequency of repairs or part replacements.

The benefit extends beyond durability. These materials can improve efficiency by reducing friction and enhancing flow dynamics. In industries like oil and gas or wastewater treatment, where equipment must operate continuously under extreme conditions, this level of resilience is invaluable.

Customization and Modular Configurations

Every industrial site has its own set of operational challenges, space constraints, variable fluid characteristics, power availability, or throughput demands. Off-the-shelf pump solutions often don’t meet the exact needs of these complex environments.

To address this, many manufacturers are offering modular pumping systems that can be customized based on application requirements. Modular pumps allow for easy scalability, faster assembly, and streamlined maintenance. Components can be swapped or upgraded without replacing the entire system, making them ideal for evolving operational needs.

Custom configurations extend to mobile and submersible options, which offer added flexibility in remote or underwater operations. These tailored solutions enable businesses to get maximum value and performance from their investment without compromising adaptability.

Advanced technologies are ushering in a new era of industrial pumping, one defined by intelligence, efficiency, and resilience. From smart sensors and predictive analytics to customized designs and high-performance materials, modern pumps are more than mechanical tools, they are strategic assets that contribute directly to operational success.

By staying informed about these technological advancements and partnering with forward-thinking manufacturers, businesses can improve uptime, lower energy costs, and extend the life of their equipment. As industries continue to face higher demands and tighter margins, the integration of advanced pumping solutions isn’t just a smart move, it’s a competitive necessity.